Customized Coloring

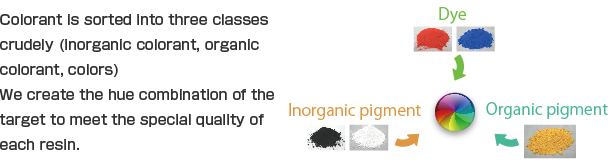

We make efforts to transmit the know-how of the colorant which has been passed through the various regulations, utilization of CCM, and raising up a mixing-colors engineer, and accomplish a high qualified customized coloring from general-purpose resin to high performed resin.

Coloring

Hue control

- choice of required colorants

- blending of resin and colorants

- blending

- produce of plate

- confirmation by means of colorimeter

- completion of color-matching plate

Production

- Method to apply colorants to natural resin directly It has advantage of delibery period and cost.

- MB means resin perret kneaded high condensed colorants.

This is to mix with natural resin.

Cost advantage is created by high magnification.

- Colored perret is a name of product to knead colorants and natural resin together.

From the view of quality, it makes quality become most stable compared with Dry coloring and Masterbatch blend.